.jpg)

|

Shijiazhuang TianYue Honest Co., Ltd.

|

weave mesh

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

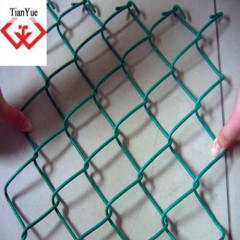

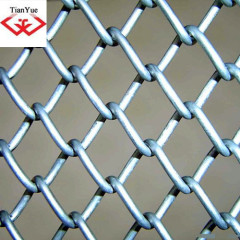

chain link fence

1link and weave simple,artistic,practical

2strong and durable

3 woven diamond pattern

1) Application process of chain link fence

Select high-quality low-carbon steel wire rod, then make it into the appropriate thickness low-carbon steel wire with the drawing machine.

(2) Surface treatment makes the low-carbon steel wire into PVC wire, electrical galvanized wire, hot-dipped wire. About zinc thickness of the hot-dipped galvanized wire, we can make as the clients requirement.

(3) Weaving: Using the development machinery to make the surface treatment finished low-carbon steel wire into per-forming form, then linking them together.

(4)The edge of the chain link fence: It is divided into two types. One type is a hem on, the other is a twisted on. Using special tools to make the edge hemming or twisting. The hemmed edge is more popular compared with the twisted edge. Customers can choose according to their own needs.

(5) The contraction of chain link fence: We use the advanced machines to make the roll diameter for chain link fence into the smallest one, in order to save transportation costs by saving volume.

(6) Packing: Wrap up the two edges of the crimpled rolls with the plastic weaving bags

Select high-quality low-carbon steel wire rod, then make it into the appropriate thickness low-carbon steel wire with the drawing machine.

(2) Surface treatment makes the low-carbon steel wire into PVC wire, electrical galvanized wire, hot-dipped wire. About zinc thickness of the hot-dipped galvanized wire, we can make as the clients requirement.

(3) Weaving: Using the development machinery to make the surface treatment finished low-carbon steel wire into per-forming form, then linking them together.

(4)The edge of the chain link fence: It is divided into two types. One type is a hem on, the other is a twisted on. Using special tools to make the edge hemming or twisting. The hemmed edge is more popular compared with the twisted edge. Customers can choose according to their own needs.

(5) The contraction of chain link fence: We use the advanced machines to make the roll diameter for chain link fence into the smallest one, in order to save transportation costs by saving volume.

(6) Packing: Wrap up the two edges of the crimpled rolls with the plastic weaving bags

Opening | Wire Gauge SWG | Wire Diameter (mm) | Weight (kg/m2) | |

inch | mm | |||

1/2" | 12.70 | 14# | 2.2 | 4.4 |

3/4" | 19.05 | 12# | 2.8 | 6.0 |

3/4" | 19.05 | 14# | 2.2 | 3.3 |

3/4" | 19.05 | 16# | 1.63 | 1.9 |

1" | 25.40 | 12# | 2.8 | 4.0 |

1" | 25.40 | 14# | 2.2 | 2.4 |

1.1/4" | 31.75 | 12# | 2.8 | 3.2 |

1.1/4" | 31.75 | 14# | 2.2 | 1.92 |

1.1/2" | 38.10 | 10# | 3.25 | 4.1 |

1.1/2" | 38.10 | 12# | 2.8 | 2.7 |

1.1/2" | 38.10 | 14# | 2.2 | 1.6 |

2" | 50.80 | 8# | 4.06 | 4.6 |

2" | 50.80 | 10# | 3.25 | 3.1 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Dutch Weave Wire Mesh

Dutch Weave Mesh

Plain Weave Mesh

Twill Weave Mesh

Plain Dutch Weave Mesh

Wire Mesh Dutch Weave

More>>

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)